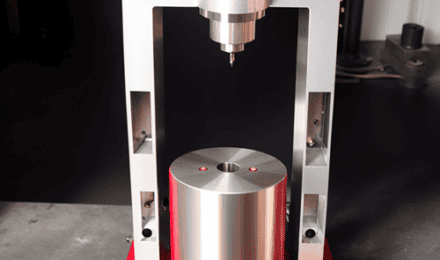

The CNC Hydraulic Press engineering machinery is one of the crucial pieces of equipment in the construction industry. They are mostly used for site constructions, which are usually a very harsh environment. This means the rate of wear and tear due to friction and other factors is high. Therefore, maintenance of these machines and, more so, lubrication with hydraulic oil is highly recommended.

But most drivers and maintenance personnel often ignore the maintenance schedules as provided by the manufacturer. Maybe they don’t want to spend, or they just lazy. There are also major lubrication misunderstandings that end up badly for the hydraulic press. Here are common mistakes people make:

Does The Machine Need Lubrication?

This question causes doubts, and the answer could be no despite the manufacturer’s schedule. differences in working methods and parts’ conditions could raise these doubts. The manufacturer manual usually comes with strict requirements for the lubrication of various machine points. These guidelines must be followed strictly for proper lubrication. If it’s time to change the oil, it must be done without asking questions.

I’ve Already Added Oil, Is It Still Under Lubrication?

When it comes to lubricating a CNC hydraulic press machine, there are many factors that you need to consider. First, you need to understand that every part that needs lubrication is different. It should, therefore, be lubricated as recommended by the manufacturer. The working methods and ambient temperature of the machine have different lubrication requirements. It depends on the parts you are lubricating and the condition the machine is working in.

Add More Lubricant, No Harm?

This is another mistake that CNC hydraulic press machine users make. There are many factors that determine the amount of lubrication for certain parts of the machine. Maybe the structural type and use condition. Follow the provided regulations by the manufacturer manual. Checking the oil level and strictly following operation instructions can be very helpful. Do note that excessive refilling of the lubricating oil could be harmful and waste. Do add oil for the sake of adding.

After Adding Lubricating Oil, It Dries Quickly?

This is one of the misunderstandings that some hydraulic machines have. The hydraulic oil simply creates a certain thickness of oil film between two parts of the machine that move with each other. The oil film between the parts creates a certain thickness that keeps the parts from each other. That’s how friction between machine parts is reduced. In addition to that, lubricating cools the part as well as reducing wear and tear.

The Oil Is Leaking, Change The Sealing Ring?

If the CNC hydraulic press machine lubricating oil is leaking, then you are exposing it to damages. Oil leaks mean that the sealing rings are damaged, or they have worn out beyond repair. You should change them immediately to avoid leaks. The sealing must have certain properties such a good elasticity to produce a certain degree of compression and deformation amid pressure. Ensure the same size sealing ring has been used for replacement.

Should I Clean The Part When Replacing Sealing Ring?

Sealing rings wear our pretty fast and should be replaced immediately. But one common mistake people make when replacing sealing rings is leaving the machine part dirty. This eventually affects the effectiveness of the seals. When replacing the sealing ring, make sure the open part of the hydraulic machine is thoroughly cleaned. Make sure the seal is not damaged during replacement as its membrane could be soft.

Spare Seal Ring, Just Leave It Casually?

The answer is NO. Most CNC Hydraulic Press engineering machinery users make this mistake of poor storage of spare seal rings. It would be best if you had a spare seal ring for you in case of an emergency. But these seals can easily get damaged by things like sunlight hence making them ineffective. That’s why proper storage is recommended.

The Oil Is Dirty, Pour It!

The hydraulic oil may have chemicals that can be harmful to the environment if poured. But if the dirty oil is only mixed with metal, it can be reused after treatment. There are rough processing pieces of equipment that can use this oil after simple treatment. So, you might make extra money selling this oil to other dealers and at the same time save the environment.