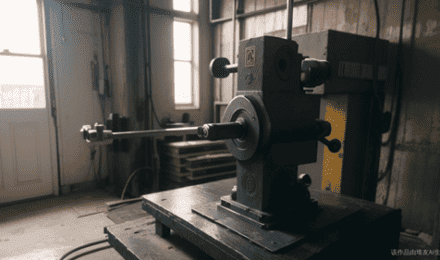

Servo hydraulic press, also known as servo-hydraulic press, is a hydraulic press that uses an AC servo motor to drive an internal gear pump to achieve servo control. Servo hydraulic press comprises of bow frame, stamping slider, operating table, four guide columns, upper master cylinder, proportional hydraulic system, servo electrical system, pressure sensor, pipeline, and other parts.

It has the advantages of saving electricity and fuel, low noise, and less heat generation. It is also energy-saving, emission reduction, low failure rate, and convenient maintenance. Their production cost is low and has improved production efficiency.

Here are 10 Features of the Servo-hydraulic press:

- The fuselage adopts the traditional bow structure, which is similar to the traditional mechanical punch. The structure is simple and compact. The floor space is small, and the operation is convenient.

- The master cylinder is a piston-type oil cylinder with a fast cylinder inside. It can realize high-speed descending and slow-speed pressing action, which increases productivity.

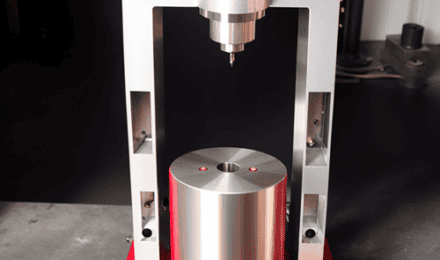

- The oil cylinder is of the upper oil cylinder type. When the stamping slider is working, it is pressed from top to bottom, the lower die is stationary, and the upper die is pressed.

- The upper part of the fuselage is equipped with a precise positioning device, a mechanical dead limit, and a servo adjustment device.

- The precise positioning device is driven by a servo motor. The positioning accuracy is 0.01mm.

- The electrical system adopts PLC + servo system + touch screen + proportional drive. Therefore, it cooperates with the proportional hydraulic system and sends out instructions according to the process requirements to complete the process cycle action of the machine.

- A friendly man-machine interface can access 200 sets of parameter programs at will.

- The electronic ruler determines the position, and the stroke position can be random. High-precision positioning adopts a mechanical dead limit. The theoretical positioning accuracy is ±0.01mm, and the actual positioning accuracy is 0.01-0.02mm.

- The pressure detection is by the pressure sensor, and the machine’s pressure setting is arbitrary.

- Automatic feeding of the mobile worktable

The main purpose of the servo-hydraulic press:

- They are common for tooling pressing in motors, auto parts, home appliances, and electronics industries.

- For the pressure constant pressure system

- Good for compression and extension test systems.

- Imprinting, forming, shallow drawing, shaping, and pressure assembly of metal or non-metal parts, etc. Glasses, hardware products pressing.

Can press products like watchcases, glasses, mobile phone products, tableware, signs, jewelry, parts, etc.