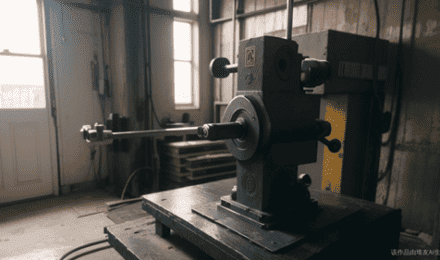

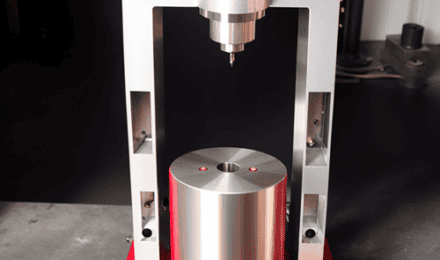

The four-column hydraulic press is a kind of mechanical equipment that uses static pressure of the hydraulic oil delivered by the oil pump to process metal, plastic, rubber, wood, powder, and other products. It is often used in the pressing process and press forming processes, like forging, cold extrusion, and stamping. They are also in straightening, bending, flanging, sheet deep drawing, powder metallurgy, press fitting, and so on.

Its principle is to make use of Pascal’s law to make use of hydraulic pressure transmission machinery. Of course, the uses are also diverse according to needs. For example, according to the type of liquid that transmits pressure, there are two major categories: hydraulic press and hydraulic press.

How To maintain a four-column hydraulic press

Great attention should be to the storage and transfer of working oil. Oil drums are crucial and marking and covering them up can help keep the machine in perfect condition. In winter, be careful not to mix the oil into the barrel due to the air condensing into moisture. Do not drop the rusty rust on the barrel skin into the barrel.

A number of preventive measures taken for the engine and other mechanical systems in winter, such as covering up anti-freezing, heating and insulating, and changing to low-viscosity working oil, are all applicable to hydraulic systems.

The four-column hydraulic press system should be checked and maintained frequently in winter and under bad working conditions. The working fluid should be changed frequently.

Common faults and maintenance methods of four-column hydraulic press

Often in the hydraulic transmission system, there are some relatively precise parts. Although people feel labor-saving and convenient for mechanical hydraulic transmission, they also feel that it is easy to damage. The main reason is not being clear about its working principle and structural characteristics. So understanding its preventive maintenance methods could be a challenge.

There are three basic “pathogenic” factors in hydraulic systems: pollution, overheating, and air intake. These three unfavorable factors have a close internal relationship. Any one of them will cause another one or more problems.

The practice shows that 75% of the “diseases” causes of hydraulic systems are by these three factors:

- The working fluid has deteriorated due to contaminants

- Overheating

- Air entry

Carry out the cleaning and assembly of some major precision parts in the system should in a very clean room. The room should have a clean floor and closed doors and windows. In addition to that, keep the temperature within 200C for the machine to operate perfectly.

The above is an overview of the primary maintenance method for the four-column hydraulic press. For more information, please click on the BLY official website to view.