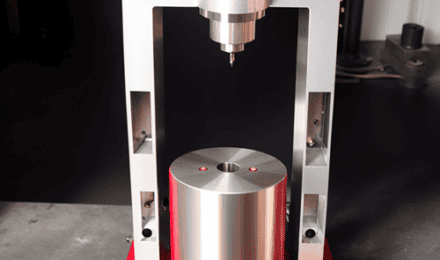

Hydraulic presses play an important role in the automotive industry for shaping and forming metal parts. They utilize hydraulic power to generate tremendous compressive forces for molding, pressing, punching, shearing, and forming operations.

Automotive Applications of Hydraulic Presses:

Sheet Metal Forming

The automotive industry widely uses hydraulic presses for sheet metal forming. Body panels, doors, hoods, and fenders need to be pressed into complex shapes from flat metal sheets. Workers place the metal sheets between precision-ground die sets in the hydraulic presses. The hydraulic presses then apply huge pressure by pressing the die punches to form the sheets into the desired shapes. Manufacturers use enormous hydraulic presses that can apply thousands of tons of pressure to form steel and aluminum sheets into body panels.

Body Assembly Presses

Once individual body panels are formed, they need to be joined together into sub-assemblies and the full body shell. Hydraulic body assembly presses play a vital role in this stage. They are used to join interior and exterior body panels together by applying localized pressures across the surface area. Assembly presses need to generate enough force to seal joints but also maintain precision across large surface areas. Modern hydraulic assembly presses are CNC controlled for precise positioning and force application. They have programmable rams that can apply pressure across multiple points of a panel for accurate assembly.

Trimming and Piercing

After body panels are pressed and assembled, they often need additional trimming and piercing operations. Hydraulic trimming presses use specialized dies to punch holes, trim edges, and cut openings in body components. Trimming presses are essential for creating mounting holes, wheel wells, door openings, engine bay holes, and other precise cut-outs in formed panels. Piercing presses can punch small holes with great accuracy for things like wiring harnesses and interior mounts. The hydraulic power allows consistent trimming and piercing across production runs.

Stamping Presses

Automotive manufacturers use heavy duty hydraulic stamping presses to cut, shape, and form metal blanks into finished parts like hoods, doors, fenders, roof panels, and trunk lids.These presses utilize a single die set to stamp the entire contour profile of a panel in one or two strokes. Modern hydraulic stamping presses deliver thousands of tons of pressure between the die set to form complex shapes rapidly and consistently. They enable high productivity and precision essential for automotive manufacturing.

Hydroforming Presses

Hydroforming is an specialized type of hydraulic forming used to form irregular, concave shapes that would be difficult with standard die stamping. In hydroforming, workers use pressurized fluid to inflate a metal tube inside a die cavity. This inflation causes the tube to expand and take the shape of the die. Hydroforming presses enable shaping complex tubular automotive parts like engine cradles, radiator supports, and chassis components. The hydraulic pressure uniformly stretches and forms the tubing into strong, lightweight parts.

Punching and Blanking

Automotive manufacturers use hydraulic punching and blanking presses to cut out internal features and profiles in metal sheets. These presses use a punch-and-die set to punch holes or cut precise shapes in sheet metal. In blanking, a shape is cut entirely through a sheet, separating it from the surrounding material. Punching presses are essential for making brackets, brackets, cradles, and other automotive components. They enable high speed, repeatable precision punching operations.

Equipment Manufacturing

Hydraulic presses are also necessary for manufacturing the automotive production equipment itself. Presses are employed to shape and assemble molds, dies, jigs, fixtures, and custom machinery required for auto production lines. Large presses produce enormous injection molds, die-casting molds, and die sets used in the presses and stamping equipment itself. Hydraulic presses enable robust production of durable equipment essential for high-volume auto manufacturing.

Benefits of Hydraulic Presses in the Automotive Industry:

High Force and Precision:

Hydraulic presses can generate significant force, enabling the deformation of tough materials used in automotive manufacturing. The ability to exert precise force allows for the production of intricate components with tight tolerances, ensuring a perfect fit and reducing the need for secondary machining operations.

Increased Efficiency and Productivity:

The use of hydraulic presses in automotive manufacturing improves production efficiency and productivity. These machines can operate at high speeds, reducing cycle times and increasing the output of finished components. Additionally, hydraulic presses can be integrated into automated production lines, further enhancing efficiency and reducing labor costs.

Versatility:

Hydraulic presses offer versatility in terms of the range of materials and components they can process. They can handle different metal alloys, plastics, and composites used in automotive manufacturing. With the use of interchangeable tooling, hydraulic presses can adapt to various production requirements, making them suitable for diverse applications in the industry.

Enhanced Safety:

Safety is a paramount concern in the automotive industry. Hydraulic presses are equipped with safety features such as pressure sensors, emergency stop buttons, and safety guards to protect operators from accidents. These features ensure that the machines operate safely and reduce the risk of injuries.

Conclusion:

hydraulic press technology enables many key manufacturing processes in the automotive industry. From deep drawing of body panels to trimming finished components, hydraulically powered presses are critical for shaping sheet metal into complex automotive parts. The pressing forces enable forming, cutting, joining and assembly operations that would be impossible through manual labor. Hydraulic presses provide the productivity, precision, and reliability needed for modern auto manufacturing.