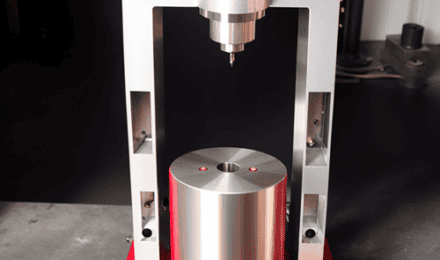

Hydraulic presses, known for their ability to generate immense force through the application of fluid mechanics, are an essential part of many industrial processes. These machines operate by leveraging Pascal’s principle, which states that any change in pressure in an enclosed fluid is transmitted uniformly in all directions. This property allows hydraulic presses to apply tremendous force over a relatively small area, making them ideal for tasks such as forging, molding, punching, and clinching.

Selecting the right hydraulic press for your specific needs, however, is a complex task. It’s not as straightforward as simply choosing the most powerful or the heaviest press. Instead, the decision should be based on a range of factors, including the machine’s weight, power, size, and the specific tasks it will need to perform. In this article, we will focus on one of these aspects: choosing the right hydraulic press based on its weight.

Why is Weight an Important Consideration?

The weight of a hydraulic press is directly linked to its capacity to generate force. A heavier press typically has a larger hydraulic system, which can generate and withstand more pressure. This makes heavy hydraulic presses ideal for tasks that require a lot of force, such as bending or shaping thick metal plates.

But there’s more to the story than just force. The weight of a hydraulic press also impacts its stability and durability. Heavier presses are generally more stable than lighter ones, reducing the risk of tipping or moving during operation. They are also often more robustly built, which can increase their lifespan and decrease the need for maintenance and repairs.

However, a heavier press may not always be the best choice. They can be difficult to install and move, and they require a strong, stable surface to support their weight. These factors can increase the operational and installation costs associated with heavy hydraulic presses, making them less suitable for some applications.

Factors to Consider When Choosing a Hydraulic Press Weight

1. Assessing Application Requirements

To determine the optimal weight for your hydraulic press, it is important to assess your specific application requirements. Start by identifying the maximum load or force that the press needs to handle. Consider the size and dimensions of the workpieces you will be working with. Larger and heavier workpieces may require a hydraulic press with a higher weight capacity to maintain stability and prevent equipment failure.

Analyzing the frequency and intensity of your operations is also crucial. If your operations involve continuous and heavy-duty tasks, a heavier press may be more appropriate to ensure durability and longevity. On the other hand, if your operations are more intermittent or involve lighter tasks, a lighter press could still meet your needs while offering greater portability and flexibility.

It is also important to consider future expansion or diversification plans. If you anticipate your operations growing or evolving over time, choosing a hydraulic press with a slightly higher weight capacity than your current requirements can provide room for scalability and prevent the need for an upgrade in the near future.

2.Considering Stability and Durability

The weight of a hydraulic press directly affects its stability. A heavier press provides a solid foundation, minimizing vibrations and movement during operations. This stability is crucial for maintaining accuracy and precision, especially when working with delicate or high-precision tasks. Additionally, stability contributes to the overall safety of the equipment and the operators.

Durability is another critical factor influenced by weight. A heavier press is often associated with robust construction and materials that can withstand the demands of heavy-duty applications. When considering the weight of a hydraulic press, evaluate the quality of construction and materials used, ensuring they can withstand the forces and stresses exerted during operations.

Furthermore, consider the press’s vibration and shock absorption capabilities. A heavier press tends to absorb vibrations better, reducing the risk of damage to the equipment or workpieces. This is particularly important when working with materials that are sensitive to vibrations or when performing tasks that require high precision.

3. Importance of Portability and Space Constraints

While stability and durability are important, portability and space constraints may also factor into your decision-making process. If you frequently need to move or transport the hydraulic press between different locations, a lighter press may be more practical. Lighter presses are generally easier to handle and transport, making them suitable for mobile operations or industries that require flexibility.

Consider the available space in your workspace as well. If you have limited space, a lighter press with a smaller footprint can be advantageous. It allows for better maneuverability, optimizing the utilization of your workspace without compromising on performance.

However, it is important to strike a balance between weight and portability. While a lighter press offers greater mobility, it may sacrifice stability and load capacity. Assess your specific needs and find the optimal weight that aligns with both your portability requirements and operational demands.

4. Consulting Manufacturer’s Guidelines and Recommendations

Manufacturers provide guidelines and recommendations for their hydraulic presses, including weight specifications. These guidelines are based on extensive research, testing, and engineering considerations. It is highly recommended to consult the manufacturer’s guidelines to ensure you choose a hydraulic press that meets their recommended weight range for your intended applications.

Furthermore, consider industry standards and regulations when selecting a hydraulic press. Some industries have specific requirements regarding weight, load capacity, and safety standards. Adhering to these standards ensures compliance and guarantees the suitability of the hydraulic press for your industry-specific needs.

Seeking expert advice from manufacturers or distributors can also provide valuable insights. They can help assess your requirements, recommend the appropriate weight range, and offer guidance on selecting the right hydraulic press for your specific applications.

Conclusion

Selecting the right hydraulic press is a critical decision that can significantly impact your operation’s efficiency and productivity. While the weight of the press is an important factor, it should not be the sole determinant. Instead, it should be considered alongside other factors such as the press’s power, size, and the specific tasks it will need to perform.

Remember that every application is unique, so there’s no one-size-fits-all solution. It’s crucial to understand your specific needs and constraints before making a decision. Don’t hesitate to engage with hydraulic press manufacturers and experts, who can provide valuable insights and guidance based on their experience and expertise.

In the end, the right hydraulic press for you is the one that best fits your needs and circumstances, providing the optimal balance between weight, power, size, and cost.