Hydraulic presses are versatile tools used in a variety of industries like manufacturing, automotive, and engineering. They use the principles of hydraulics to generate a compressive force, making them ideal for molding, shaping, and pressing objects. But with great power comes great responsibility – it’s crucial to understand how to use a hydraulic press safely and effectively. In this article, we’ll explain how to operate a hydraulic press step by step.

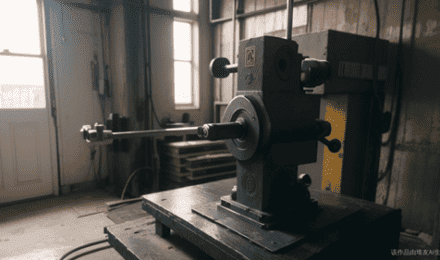

Understanding a Hydraulic Press

A hydraulic press consists of several key components, each playing a crucial role in its operation:

- Hydraulic System: This includes a hydraulic pump, reservoir, valves, and hoses. The hydraulic pump supplies pressurized fluid to generate force.

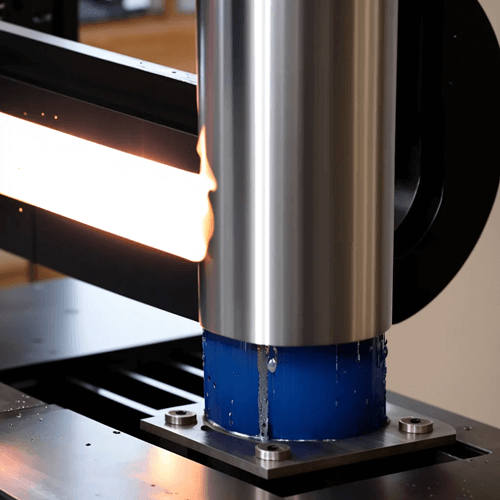

- Cylinder: The cylinder houses the piston, which moves up and down based on hydraulic pressure and applies force to the material being pressed.

- Ram: The ram is the flat surface attached to the piston. It exerts pressure on the material and enables precise control of the pressing process.

- Control Panel: The control panel allows you to adjust pressure settings, monitor the process, and activate safety features.

Safety Measures

Before starting to use a hydraulic press, ensure you follow these safety measures:

- Wear Protective Equipment: Always wear safety glasses, gloves, and sturdy footwear.

- Check the Machine: Before each use, inspect the press for any defects or leaks. Make sure the pressure gauge is working correctly.

- Clear the Area: Ensure the area around the press is clear of any unnecessary objects or debris.

- Never Exceed the Press’s Capacity: Overloading the press can cause serious damage or accidents. Always stick to the manufacturer’s recommended maximum load.

Preparing the Hydraulic Press

Before commencing any operations, ensure the hydraulic press is in proper working condition:

- Check Fluid Levels: Verify that the hydraulic fluid levels are sufficient and that the fluid is clean. If necessary, add or replace the fluid following the manufacturer’s instructions.

- Inspect the Machine: Examine the press for any signs of damage or wear. Check the hoses, valves, and connections for leaks or loose fittings. Address any issues before proceeding.

- Adjust Pressure Settings: Set the desired pressure level on the control panel according to the material and task at hand. Refer to the manufacturer’s guidelines for recommended pressure settings.

Positioning and Preparing the Material

Proper positioning and preparation of the material are essential for successful pressing:

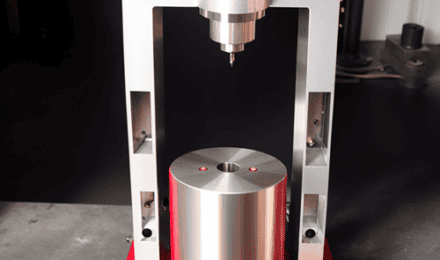

- Material Alignment: Place the material to be pressed between the ram and the bed or an appropriately sized die. Ensure it is centered and aligned correctly.

- Support and Fixation: Depending on the material and task, use support blocks, fixtures, or clamps to secure the material in place, preventing unwanted movement during the pressing process.

Operating a Hydraulic Press

Now, let’s walk through the steps of operating a hydraulic press:

- Setup: Place the object you wish to press on the center of the press plate. Ensure it’s stable and well-aligned with the press above.

- Adjustment: Adjust the press to the correct height. Most presses have a wheel or lever that allows you to move the press plate up and down.

- Pressurizing: Start the pump to increase the pressure in the cylinder. The piston will start to move, lowering the press onto your workpiece.

- Application of Pressure: Continue increasing pressure until the desired result is achieved. Monitor the pressure gauge to ensure you do not exceed the press’s capacity.

- Releasing: Once you’ve achieved the desired result, release the pressure. Most hydraulic presses have a release valve that allows the hydraulic fluid to flow back into the reservoir, raising the press plate.

- Removal: Once the press plate has fully risen, you can remove your workpiece.

Remember, always follow the manufacturer‘s instructions for your specific hydraulic press model.

Post-Operation Maintenance

To ensure the longevity and optimal performance of your hydraulic press, perform routine maintenance:

- Cleaning: Remove any debris or residue from the press and its components. Wipe down the surfaces with a clean cloth and use an appropriate cleaning agent, if necessary.

- Inspection and Lubrication: Regularly inspect the press for signs of wear or damage. Lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

- Storage: When not in use, store the hydraulic press in a clean, dry environment. Follow the manufacturer’s guidelines for proper storage and ensure it is securely locked to prevent unauthorized access.

Conclusion

Using a hydraulic press can open up a world of possibilities for shaping and manipulating various materials. By following the step-by-step guide outlined above, you can harness the immense power of a hydraulic press while prioritizing safety and achieving precise results. Remember to always consult the manufacturer’s instructions and exercise caution throughout the process to make the most of this remarkable machine.