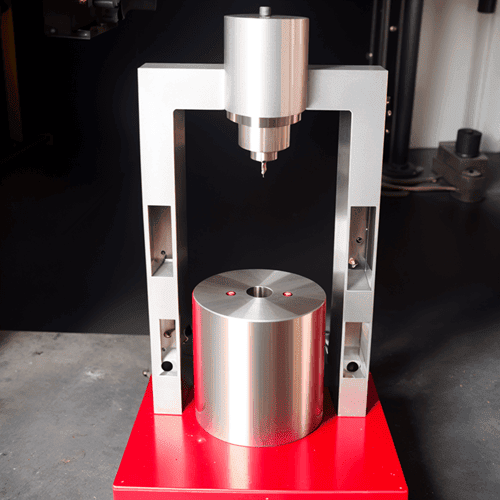

Introduction to Hydraulic Presses

A hydraulic press is a tool that uses hydraulic pressure to generate a compressive force. It’s a useful tool for various tasks, such as forming metal, pressing bearings, or crushing just about anything you’d like. While industrial presses are large and expensive, you can build a small hydraulic press for home use. This article will guide you through the process.

Disclaimer: Given that this project involves the use of power tools and hydraulic equipment, it is crucial to prioritize safety precautions throughout the construction process. It is imperative to exercise caution and adhere to proper safety measures at all times. Therefore, only embark on this project if you are confident in your abilities and have the necessary knowledge and experience.

Materials and Tools Needed for Building a Small Hydraulic Press

- Hydraulic Jack (6-ton capacity is a good starting point)

- Steel Plates (2 pieces, 10″x10″x1/2″)

- Steel Channel (6 pieces, 2″x2″x1/4″, 10″ length)

- Bolts and Nuts (8 sets, 1/2″ diameter, 2.5″ length)

- Hydraulic cylinder (with appropriate size and capacity)

- Hydraulic pump

- Hydraulic hoses and fittings

- Control valves

- Pressure gauge

- Hydraulic fluid

- Welding equipment (if necessary)

- Basic hand tools (wrenches, socket set, etc.)

Steps to Build a Small Hydraulic Press

1. Designing the Frame

To construct the frame of your hydraulic press, start by aligning two pieces of steel channel in a parallel configuration. Then, proceed to weld a third piece across one end, effectively creating a U-shape. Subsequently, replicate this process using the remaining three pieces of steel channel. As a result, you will have two U-shaped components that will serve as the sides of your press frame. Consequently, these two U-shaped pieces will serve as the sides of your press frame.

2. Frame Fabrication

Using the steel components, cut and weld the frame according to your design. Ensure that the frame is sturdy and capable of withstanding the forces generated during operation. Take care to align the parts accurately and reinforce critical joints.

3.Install the Hydraulic Cylinder

Position the hydraulic cylinder vertically within the frame and secure it firmly using bolts or welding. Ensure that the cylinder is aligned properly and securely fastened to prevent any movement during operation.

4.Connect the Hydraulic Pump

Once you have determined a suitable location, proceed to install the hydraulic pump in close proximity to the hydraulic cylinder. Ensure that the pump is positioned conveniently and securely. Next, establish the connection between the pump and the cylinder by employing hydraulic hoses and fittings. Be diligent in following the manufacturer’s instructions meticulously to ensure proper installation. Additionally, prioritize the security of the connections, verifying that they are tightly fastened and leak-free.

5.Attach Control Valves

Install control valves to regulate the flow of hydraulic fluid. These valves allow you to control the speed and pressure of the hydraulic press. Connect them to the hydraulic pump and cylinder using hoses and fittings. Ensure that the valves are easily accessible and properly labeled.

6.Add a Pressure Gauge

Install a pressure gauge on the hydraulic system to monitor the pressure exerted by the press. Mount it in a visible location, preferably near the control valves. Connect the pressure gauge to the hydraulic circuit, ensuring a secure and leak-free connection.

7.Fill the Hydraulic System

Fill the hydraulic pump reservoir with the recommended hydraulic fluid specified by the manufacturer. Be mindful of the fluid type and quantity required. Follow the manufacturer’s instructions for proper filling and bleeding any air from the system using the recommended procedure.

8.Test and Adjust

Perform a thorough test run of the hydraulic press to ensure everything is functioning correctly. Check for any leaks and verify that the control valves are responsive. Gradually increase the pressure while monitoring the pressure gauge and adjust the control valves to achieve the desired pressure and speed.

Safety Measures When Using a Hydraulic Press

- Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and protective clothing.

- Follow the manufacturer’s instructions and guidelines for the hydraulic components.

- Be cautious of high pressures and forces involved in hydraulic systems.

- Regularly inspect the hydraulic press for any signs of wear, leaks, or malfunction.

- Never exceed the recommended pressure limits specified for your hydraulic components.

- Keep a safe distance and ensure others are clear of the press during operation.

- Seek professional assistance or guidance if you are not experienced in working with hydraulic systems.

Additional Details and Notes for Building a Small Hydraulic Press

- Frame Construction: When fabricating the frame, it is essential to ensure that it is rigid and capable of withstanding the forces generated during operation. Consider the thickness and strength of the steel components used, especially at critical joints and load-bearing areas.

- Welding: If you’re using welding to join the frame components, ensure that you have the necessary welding skills and equipment. Proper welding techniques, such as clean welds and adequate penetration, are crucial for the structural integrity of the hydraulic press.

- Hydraulic Cylinder Selection: Choose a hydraulic cylinder that suits your intended applications. Consider factors such as stroke length, bore diameter, and maximum working pressure. Ensure that the cylinder’s capacity matches the force requirements of your projects.

- Hydraulic Pump: Select a hydraulic pump that can provide the required flow rate and pressure for your hydraulic press. The pump should be compatible with the power source available (electric or manual) and capable of delivering sufficient force for your intended applications.

- Control Valves: Choose control valves that allow for precise control of the hydraulic fluid flow. The valves should provide options for adjusting pressure and flow rate to suit different tasks. Consider using valves with a pressure relief feature for safety purposes.

- Pressure Gauge: Install a reliable pressure gauge that can accurately measure the hydraulic pressure within the system. Ensure that the pressure gauge has an appropriate range for the expected pressures during operation.

- Hydraulic Fluid: Select a hydraulic fluid that meets the specifications recommended by the hydraulic component manufacturers. The fluid should have the necessary viscosity and lubricating properties to ensure smooth operation and minimize wear.

- Safety Features: Consider incorporating additional safety features into your hydraulic press, such as emergency stop buttons, guards, or limit switches to prevent overloading or accidents.

- Maintenance and Inspection: To ensure the continued functionality and longevity of your hydraulic press, it is essential to conduct regular inspections. Regularly scrutinize your hydraulic press for any indications of wear, leaks, or damage. Additionally, adhere to a consistent maintenance schedule that encompasses key tasks such as checking hydraulic fluid levels, lubricating moving parts, and inspecting seals and fittings. By following these practices, you can identify and address potential issues promptly, thereby optimizing the performance and lifespan of your hydraulic press.

- Expandability and Customization: Depending on your specific requirements and preferences, there are various features that you may contemplate incorporating into your hydraulic press. For instance, an adjustable worktable can provide flexibility and facilitate working with different sizes and shapes of materials. Additionally, auxiliary hydraulic circuits can expand the capabilities of your press, allowing for additional functions or attachments. Furthermore, the integration of automation components can streamline operations and enhance overall efficiency. By considering these options, you can customize your hydraulic press to maximize its versatility and functionality based on your unique needs.

Remember, building a hydraulic press necessitates a solid understanding of hydraulic systems and fabrication techniques. Consequently, if you find yourself uncertain about any aspect of the construction process, it is highly advisable to seek guidance. Consulting with experts, referring to comprehensive guides, or enlisting the assistance of professionals can help guarantee both safety and optimal performance of your hydraulic press.

Conclusion:

Building a small hydraulic press can be a challenging but rewarding project for metalworking enthusiasts. By following the step-by-step instructions provided in this article and prioritizing safety throughout the construction process, you can create a functional hydraulic press that will serve you well in various metalworking applications. Remember to consult the manufacturer’s instructions and seek expert advice if needed. Happy building!