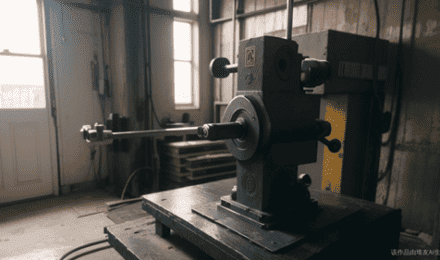

In order to enable you to better use the hydraulic press, our company now informs the following important matters concerning operation, maintenance, safety, etc.:

For proper use of hydraulic press and to get the most out of these machines, you need to take into consideration a number of things. In this guide, we have put together important matters concerning operation, safety, and maintenance, that you need to consider. Check out the following:

Operator. The hydraulic press should only be operated by a person that has been properly trained. The experience of the operator is also crucial.

The hydraulic press design is based on the user’s needs and, more so, the technical requirements for certain conditions. Everything from the hydraulic, electric system and mechanical structure must be designed to suit the user’s needs. Once done, it is difficult to change.

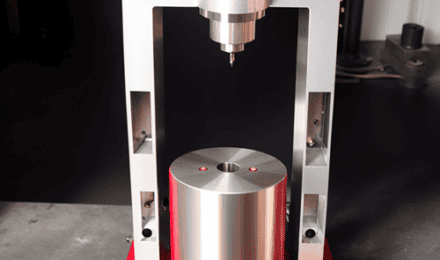

The height of the mold used for the hydraulic pressing is a factor to consider. The minimum height should not be less than the hydraulic press minimum height.

The adjustment of the safety valve of the hydraulic system should be done within the allowable value. You should never adjust it yourself, or else the issue of overloading might arise.

The limit switches should be used carefully. Do not just remove or adjust the lower and upper limit switches arbitrarily to avoid the problem of over-travel use of slider, ejector cylinder, or hydraulic cushion.

Make sure the movable parts of the hydraulic press and, more so, the slider, column, and hydraulic pad guide rails, are properly lubricated. Use the right oil for lubrication and use a lubrication pump for thorough work.

Use the right oil for the hydraulic system. YB-N46# anti-wear hydraulic oil is highly recommended. Make sure the right level of the oil is maintained. You also need to keep the oil temperature at 15℃~60℃.

Make sure that the exposed surface of the piston rod is kept clean and oiled with engine oil. If you are not using the machine, keep it oiled frequently to keep it in perfect shape.

In case the hydraulic machine develops serious oil leakage or other problems like loud noise, vibration, and impact, shut it down for inspection and fixing of the problem. The root cause of the problem must also be established and fixed for a permanent solution.

If there is a malfunction that’s proving difficult to fix, contact the manufacturer for technical help. The safety of the operator is critical and should always be observed.