Understanding the Functioning of a Hydraulic Press

The hydraulic press represents one of the most potent examples of the power of fluid dynamics, demonstrating how a small amount of force can be amplified to move an incredible amount of weight. Invented by Joseph Bramah in the late 18th century, the hydraulic press is a simple yet efficient device that has a wide range of applications, from molding metals and plastics to crushing cars in recycling plants. In this article, we will delve deep into the workings of the hydraulic press and explore the science that underlies this fascinating machine.

The Principle of Pascal’s Law

The hydraulic press operates on a principle called Pascal’s Law, named after the French scientist Blaise Pascal. In its simplest form, Pascal’s Law states that when there is an increase in pressure at any point in a confined fluid, there is an equal increase at every other point in the container. This principle is the cornerstone of hydraulic systems.

The formula for Pascal’s Law is P=F/A, where P represents pressure, F represents force, and A represents area. The principle behind the hydraulic press is that the pressure applied to a small input piston can be transformed into a larger force at the output piston. This is because, in an incompressible fluid, the pressure is the same at all points, and the force is equal to the pressure multiplied by the area.

The Basic Components of a Hydraulic Press

A typical hydraulic press includes the following main components:

- Cylinders or Pistons: A hydraulic press has two cylinders, each fitted with a piston. The two cylinders are different sizes, one large and one small, and the pistons are connected by a pipe.

- Operation Platform: This is the part of the hydraulic press where the work takes place. It’s typically sturdy and built to withstand high pressure.

- Hydraulic Fluid: This is an incompressible fluid—usually oil—that fills the system. When pressure is applied to the hydraulic fluid, it transfers that pressure throughout the entire system.

- Pump: The pump helps to maintain the pressure in the hydraulic fluid by forcing the fluid from the reservoir into the cylinders.

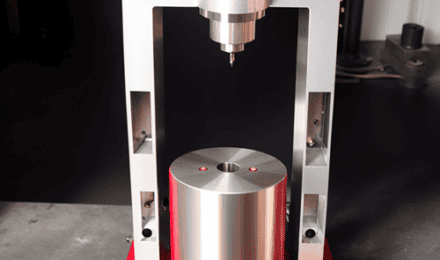

How a Hydraulic Press Works

The hydraulic press applies force by pushing the smaller piston, which puts the hydraulic fluid in the small cylinder under pressure. The hydraulic fluid pressure travels through the pipe to the larger cylinder, which moves the larger piston. The larger piston, having a greater surface area, uses this pressure to generate a larger force, which can be utilized to perform work.

When the operator presses down on the small piston, it pushes the hydraulic fluid below it and increases the pressure throughout the system. This increased pressure then pushes the larger piston up. As long as the operator maintains the force on the small piston, the larger piston will remain elevated. If the operator removes the force, the larger piston will return to its original position.

The power of the hydraulic press comes from the difference in the size of the two pistons. For example, if the small piston has an area of 1 square inch and the larger piston has an area of 100 square inches, a force of 10 pounds applied to the small piston will result in a force of 1,000 pounds at the large piston (10 pounds x 100 square inches = 1,000 pounds). This is a simple demonstration of how a hydraulic press can magnify force.

Applications of Hydraulic Presses

Hydraulic presses have a wide range of applications. Industries such as manufacturing heavily rely on hydraulic presses to perform tasks such as metal forming, deep drawing, molding, punching, and forging. Hydraulic presses are also crucial in the automotive industry for crushing cars into compact, recyclable cubes. Additionally, the construction industry uses hydraulic presses to bend or straighten large pieces of metal.

In addition, the construction industry employs hydraulic presses actively to aid in tasks such as bending or straightening large pieces of metal. They also find use in the waste management industry, where they compact waste into manageable sizes for easier disposal or recycling.

In conclusion, the hydraulic press is an ingenious application of Pascal’s Law, demonstrating how a small amount of force can be amplified to generate a powerful output. Its principle is straightforward, yet its applications are diverse and profound, underscoring the power and relevance of understanding basic physical laws in our everyday lives.

Conclusion

Hydraulic presses are powerful and versatile machines widely used across several industries. Understanding their basic principle of operation, components, applications, advantages, and safety measures can help businesses make informed decisions when selecting hydraulic presses for their operations. With their ability to generate a tremendous amount of force with relatively little effort, hydraulic presses are an essential tool for many businesses.