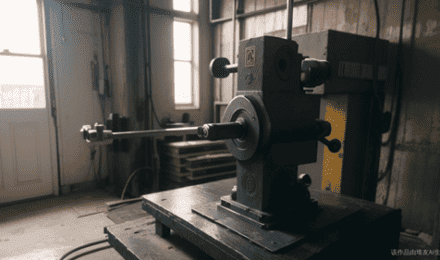

Hydraulic presses are powerful machines used in various industries for tasks such as molding, forging, clinching, and blanking. They harness the power of hydraulic pressure to generate a massive amount of force, making them essential in many heavy-duty applications. Like any other machinery, hydraulic presses require regular maintenance to ensure they operate efficiently and safely. This article will provide a comprehensive guide on how to maintain a hydraulic press.

Understanding the Basics

Before diving into maintenance, it’s essential to understand the basic parts of a hydraulic press:

- Power system: This includes the hydraulic pump and motor that generate the necessary pressure for the operation.

- Hydraulic fluid: This fluid transmits the pressure from the power system to the press.

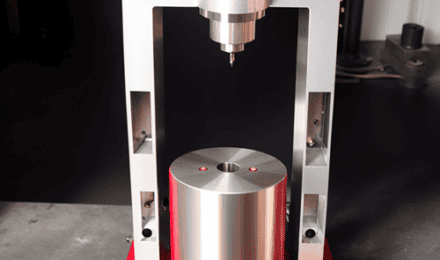

- Cylinder and Piston: The piston moves within the cylinder under the pressure of the hydraulic fluid, creating the pressing action.

- Frame: The structure that holds all the components together and provides stability during operation.

Routine Maintenance

1. Regular Inspection

Regular inspections are the first line of defense against potential issues. Depending on the frequency of use, a hydraulic press should be inspected weekly or monthly. During inspections, look for signs of wear and tear, leaks, cracks, or any other visible damage. Also, ensure that the safety guards and systems are functioning correctly.

2. Lubrication

Lubrication reduces friction between moving parts, preventing premature wear and tear. Regularly lubricate all moving parts according to the manufacturer’s recommendations. Special attention should be given to the cylinder walls and piston rings, as these are areas of high friction.

3. Hydraulic Fluid

The hydraulic fluid is the lifeblood of the press. Keep it clean and free of contaminants.

- Fluid Level: Regularly check the fluid level in the reservoir. If it drops significantly, this could indicate a leak that needs to be addressed.

- Fluid Quality: The fluid should be clear and free of visible particles. Cloudy or discolored fluid could indicate contamination, which can damage the hydraulic system. The fluid should be changed according to the manufacturer’s recommendation or if contamination is suspected.

- Temperature: Hydraulic fluid should be kept within a certain temperature range to perform effectively. If the fluid consistently runs hot, this could indicate an issue with the cooling system.

4. Cleanliness

Keeping the machine clean helps prevent contamination of the hydraulic fluid and reduces the risk of damage from debris. Wipe down the press after each use, and consider using compressed air to remove dust and debris from hard-to-reach areas.

Preventive Maintenance

1. Replacing Parts

Over time, certain parts of the hydraulic press will wear out and need to be replaced. This includes seals, gaskets, and hydraulic hoses. Always replace these parts as soon as issues are detected to prevent further damage.

2. Calibration

Proper calibration ensures the hydraulic press operates within its specified limits. Regularly check the pressure settings and adjust as necessary. Over-pressurization can lead to premature wear and potential safety hazards.

Scheduled Downtime

Planned maintenance periods, or scheduled downtime, allow for more extensive inspections, repairs, and replacements. During these periods, you can perform tasks like:

- Fluid replacement: Even with regular checks, hydraulic fluid should be completely replaced at intervals defined by manufacturer guidelines.

- Inspection of internal components: Scheduled downtime is an excellent time to inspect elements that aren’t easily accessible during routine maintenance, such as the interior of the hydraulic cylinders.

- Extensive cleaning: This is a good time to do a deep clean of the press, including the reservoir and internal components.

Training and Safety

Proper use and maintenance of the hydraulic press depend on the operators. It is, therefore, crucial to train operators on how to use and maintain the machine properly. Ensure that operators comprehend the maintenance schedule and the specific tasks to be performed during maintenance, as provided by the manufacturer’s instructions for the machine.

Additionally, train operators on how to identify and report any signs of malfunction or damage to the machine. This will enable you to address any issues promptly before they escalate into bigger problems.

Conclusion

Hydraulic presses are essential machines in various industrial applications.To ensure their optimal performance and safety, it is crucial to carry out regular maintenance tasks. These include checking the oil regularly, inspecting the hydraulic hoses, greasing the bearings, checking the electrical system, performing regular maintenance, replacing worn-out parts, and training operators on proper use and maintenance.

By following these tips, you can ensure that your hydraulic press remains in good working order and can continue to perform its critical functions in a safe and efficient manner. Remember to always consult the manufacturer’s instructions for specific maintenance schedules and tasks for your hydraulic press.

Proper maintenance of your hydraulic press will not only extend its lifespan but also reduce the risk of accidents and downtime. It is, therefore, an investment that is worth making to ensure the smooth operation of your industrial processes